PVT Coating Systems

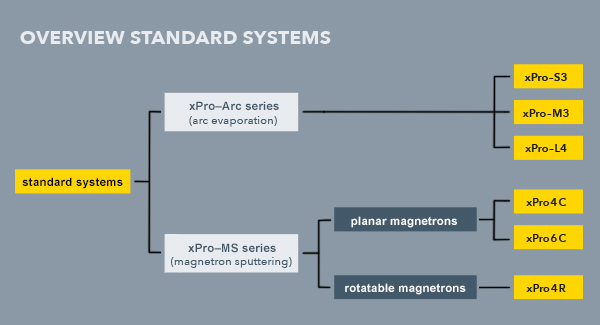

PVT offers – tailored to the customer’s application – a large portfolio of standardized or completely customized systems using arc-evaporation and magnetron-sputtering technology. All of our standard systems, named xPro (= extended productivity), are characterized by:

- high productivity

- high efficiency

- full automation

- excellent reliability in 3-shift operation

- simple operation

- easy maintenance

Our portfolio of standard coating systems can be classified base on the technology used (arc evaporation or magnetron sputtering) and the capacity (volume of the coating chamber).

Besides our standard portfolio we provide our customers tailored systems and coating solution depending on their requirements and application.

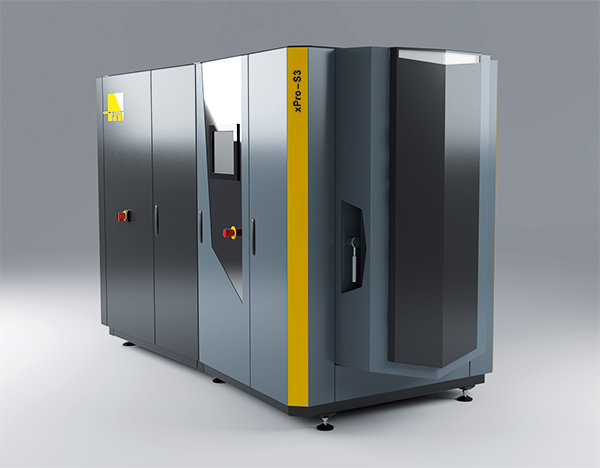

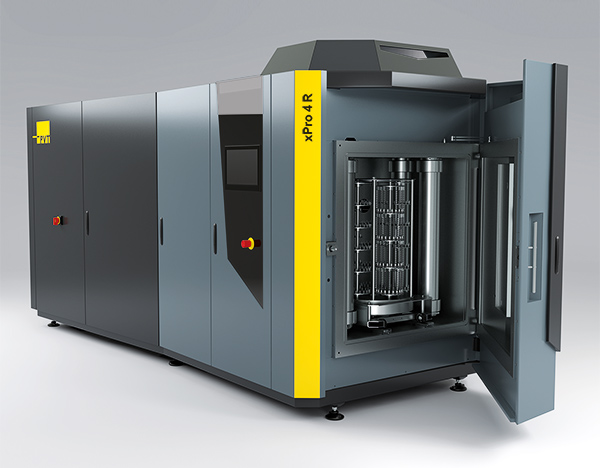

Arc Evaporation | xPro – ARC Systems

The systems are specifically designed for the deposition of high performance metallurgical coatings, such as AlCrSiN, AlTiSiN, AlCrN, AlTiN, CrN, TiC,N, TiN and many others. Such coatings are evaporated by arc onto a variety of cutting tools, dies and moulds, components and consumer products for wear and erosion corrosion protection as well as tribological purposes.

The HiParc- and PDA-technology of these systems enables faster deposition rates, shorter cycle times and significantly improved target utilisation to operate at highest output.

We offer three different system sized depending on the requirements of planned throughput.

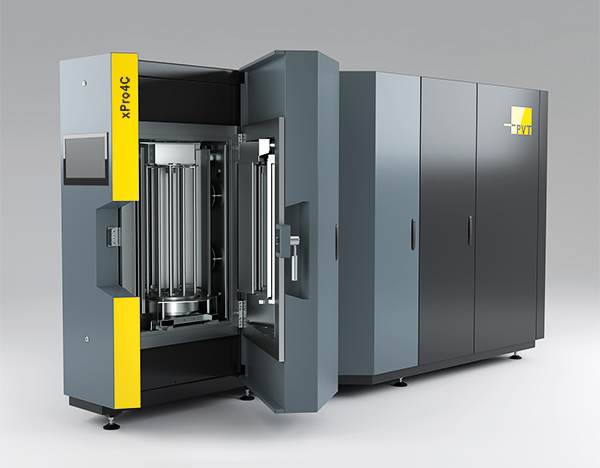

Magnetron Sputtering | xPro – MS Systems

These systems are designed to deposit coatings in HiPIMS V+ and DC-pulsed magnetron sputtering mode onto a variety of cutting tools, dies and moulds, components and consumer products.

The HiPIMS V+ and DC-pulsed magnetron sputtering mode allows an accurate control of both the flux and energy of the ion species bombarding the substrate – this is the crucial mechanism to produce coatings with optimum properties such as crystallinity, highest density, smoothness or low internal stress.

The deposition can be done as nanostructured or multi-layers for highly advantageous tribological purposes, i.e. extremely low cof (coefficient of friction) and high wear resistance.

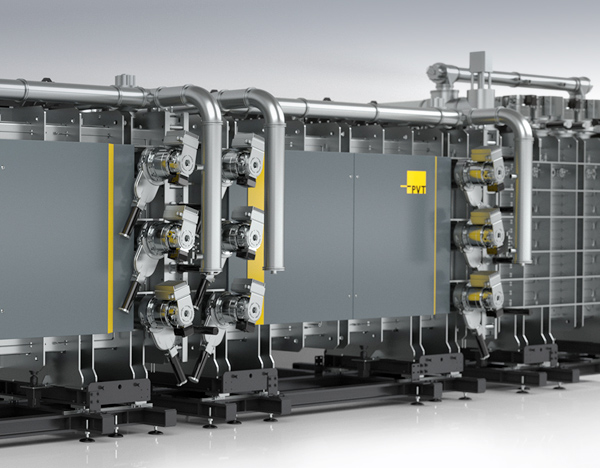

Customer Tailored Systems | xPro – Customized

Besides our standard portfolio we provide our customers tailored systems and coating solution depending on their requirements and application.

- Arc-evaporation based coating system for broaching tools up 3 meters length

- Arc-evaporation based coating system for car rims

- Arc-evaporation based system for bandsaw coating with coil diameter up to 1.5 meters

- In-Line systems for planar substrates for dimensions up to 3.5 m x 1.5 m