Even though the coatings which are deposited onto the bipolar plates of fuel cells or electrolyzers are very thin, cost are the driving factor for coating bipolar plates, i.e. cost have to be < 1 Euro/plate (plate size approx. 750 cm²).

Since both sides of a bipolar plate, typically up to 500 mm x 150 mm, have to be coated a highly productive coating process and coating equipment are essential. Several hundred bipolar plates are compiled in one stack for one single drive unit. At these numbers batch type systems are no option, since productivity is by far too low.

Systems have to operate in a continuous way, i.e. for mass production of such components the so-called in-line systems are the only option to coat substrates with high throughput from both sides at the same time without rotation.

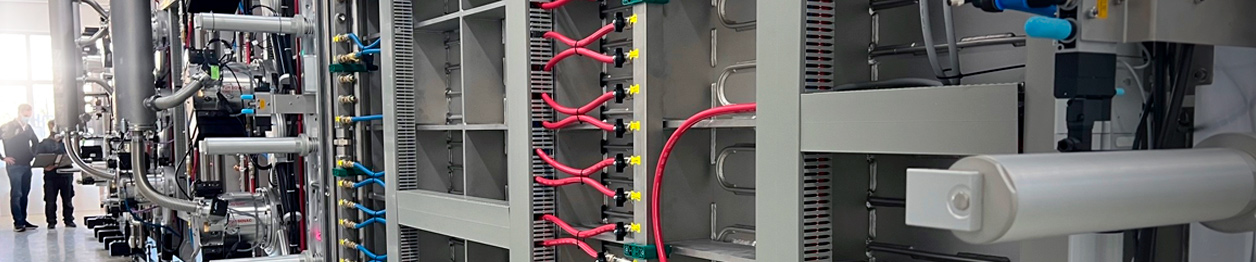

While the substrates are carried from chamber to chamber separated by large transfer valves the different process steps are carried out in dedicated chambers. The process chambers guarantee a clean environment at very stable vacuum conditions..

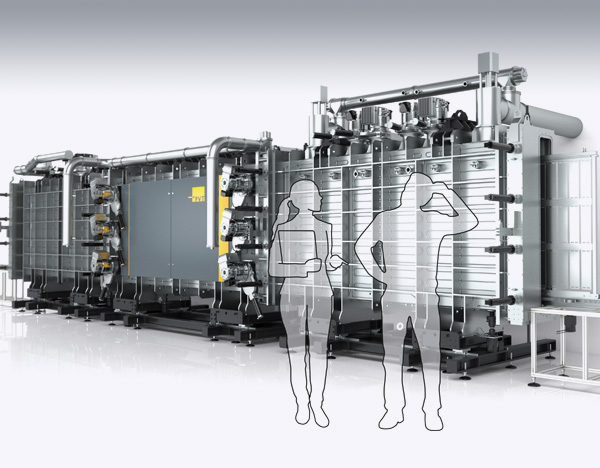

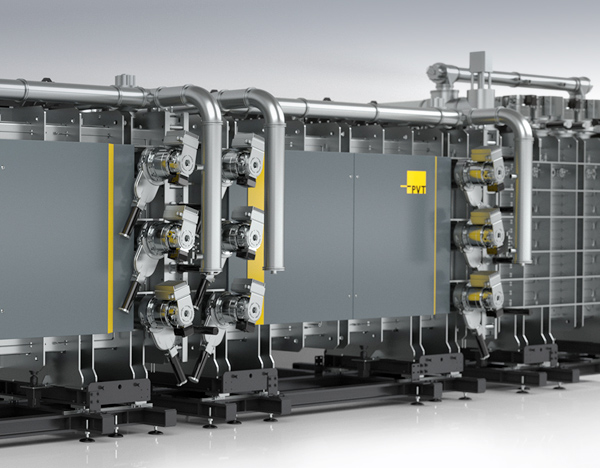

Inline-Systems i-L 4.3500 and i-L 3.5000

PVT developed for the fuel cell industry two different types of in-line systems.

In both systems, with 4 respectively 3 chambers, different coating processes can be performed, whether it is magnetron sputtering, arc evaporation or PE-CVD.

The i-L 4.3500 is a coating system which can coat 5.000.000 bipolar plates / year with the above dimensions.

The substrate carrier has a dimension of 3.5 x 1.5 m. In addition to the bipolar plates for fuel cells the larger BiPs for electrolysers can also be coated.

With the i-L 3.5000 the maximum substrate size in about 1 m x 1 m.

In both systems cost per plate are typically < 1.00 Euro, while depending on the process cost can be even significantly lower.