Analytics

Our outstanding and consistent quality is guaranteed by ongoing quality assurance measures in our in-house testing and analysis laboratories.

Our laboratories are equipped with a wide variety of measuring systems:

- Optical microscopes:

Low magnification microscopes for visual inspection of incoming and outgoing costumer tools or large-scale components

Metallurgic microscopes for evaluation of adhesion

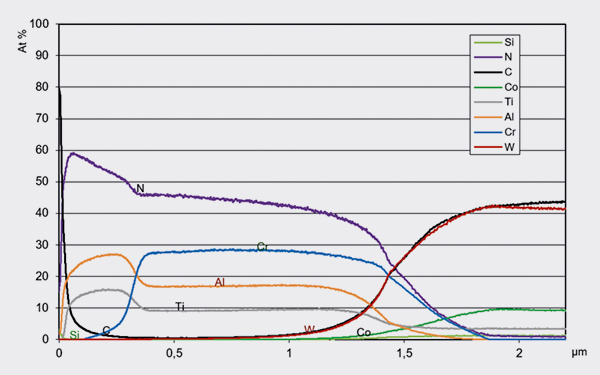

Full digital high resolution microscopes for 3D-measures of complex surfaces - GDOES (Glow Discharge Optical Emission Spectroscopy) to characterize the composition of the coatings bulk-material

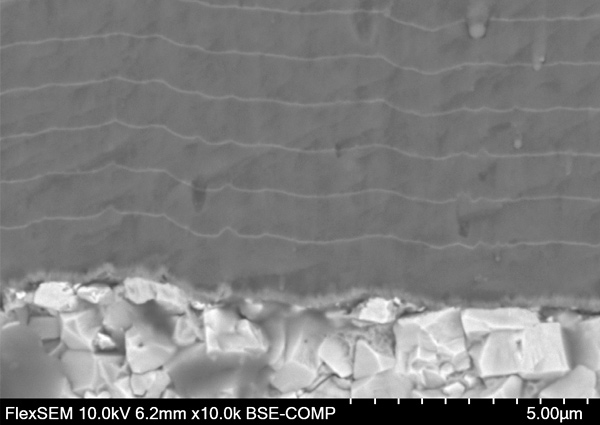

- SEM + EDX (Scanning Electron Microscope + Energy Dispersive X-ray) for composition characterization of the coatings surface material

- Profilometer for determining the surface roughness

- Cutting-edge measurement device to characterize the rounding of cutting edges

- Hardness-tester to determine adhesion according to Rockwell indentation test

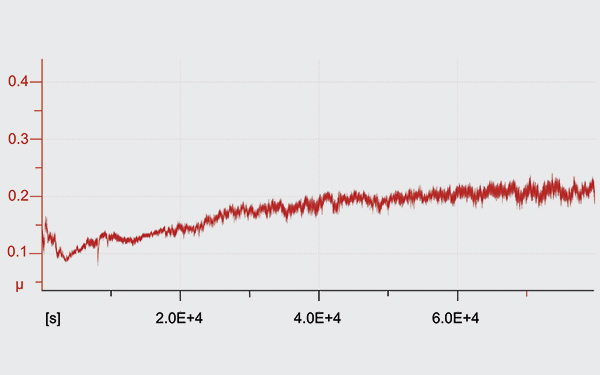

- Tribometer for measuring friction and wear

- Wide variety of other analytical test methods in cooperation with partners and institutes, such as e.g.

Nano-indentation for hardness determination

Crystallographic phase identification

Scratch test for evaluation of adhesion

Raman spectroscopy

Picture taken with SEM/EDX-system: Multi-layered AlTiN coating, thicker than 10 µm

Composition measurement done by GDOES-system

Measurement of coefficient of friction done by tribometer