Hybrid PP

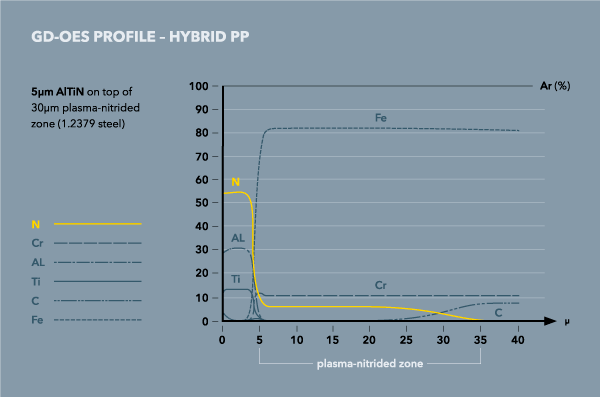

Pulse-Plasma-Nitriding and PVD-coating by ARC-evaporation – the combination of these processes create hard nitrided sub-surface regions and on top hard coatings. The combination of these processes extend the lifetime of components and dies & molds significantly.

For the Pulse-Plasma-Nitriding a separate anode is used to enhance the plasma, thus creating highly energetic Nitrogen ions which penetrate and migrate into the surface up to 100 μm deep.

Hybrid PP is a combination of processes which fortifies the surfaces in an excellent cost/performance ratio to bear the highest loads and to decrease wear and tear.