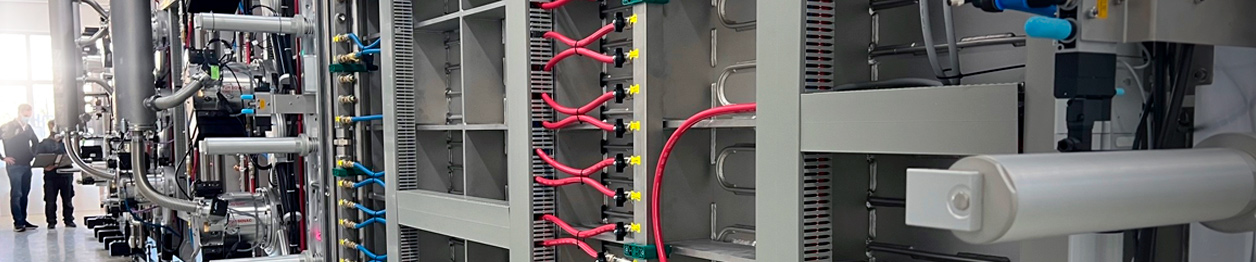

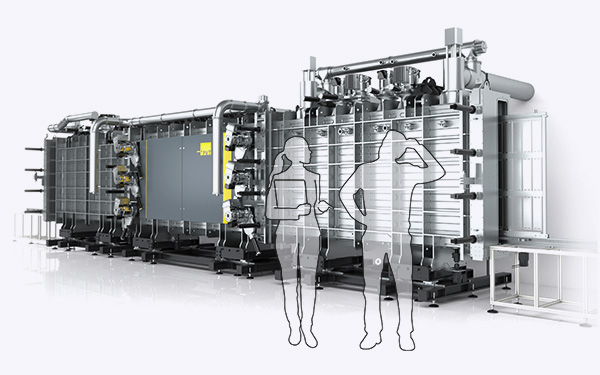

i-L 3.5000

InLine-System (> under construction)

The InLine-System i-L 3.5000 is …

The Inline-System i-L 3.5000 is characterized by:

- Robust system designed for the rigorous production environment using sophisticated vacuum coating technologies.

- Rugged construction marked by an extremely advanced highly refined design.

- Extreme reliability based on intelligent straightforward design and construction.

- The broadest spectrum of coatings and coating technology available in a single system at the lowest possible cost.

- Fully automatic, computer controlled, closed loop process control providing process repeatability, reliability and a user-friendly environment.

System Specifications

| Größe des internen Transportrahmens = maximale Beschichtungsfläche |

— × — mm |

| Größe der Bipolarplatten (BiPs) | — × — mm |

| Bipolarplatten (BiPs) Durchlauf innerhalb von 5 Minuten |

— pieces |

| Doppellagige und beidseitige Beschichtung | — nm |

| Bipolarplatten (BiPs) pro Jahr | — pieces |

| Euro pro Bipolarplatte (BiP) | — to < — |