Magnetron sputtering

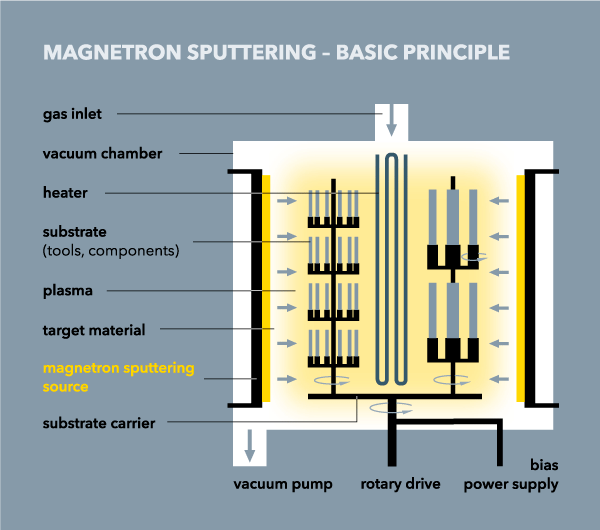

Magnetron sputtering (aka sputtering) is a process where the transfer of the coating material into the vapor phase is done by an argon ion bombardment of the coating material and releasing this way coating atoms from the target, partially ionizing them and depositing, while recombining with the reactive gases, such as e.g. nitrogen, to the desired coating material on the electrically biased substrates.

Due to the low intrinsic energy of this process and the limited throwing power the distance between the substrate and the magnetron sputtering source is significantly smaller than with arc-evaporation.

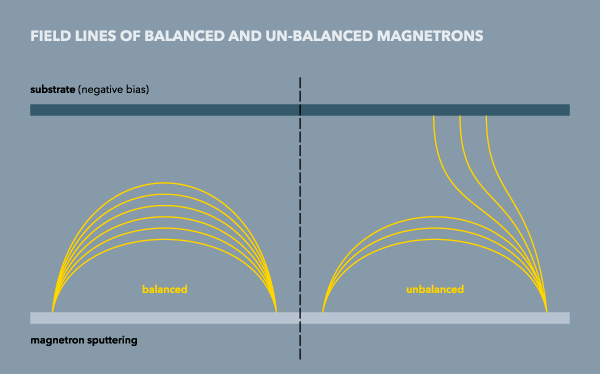

While conventional sputtering used highly balanced magnetic fields, i.e. concentrating the field lines and the discharge in front of the targets, un-balanced magnetron sputtering was developed, opening up the field lines, stretching out the plasma and thus releasing ionized particles into the coating room onto the substrates.

HiPIMS

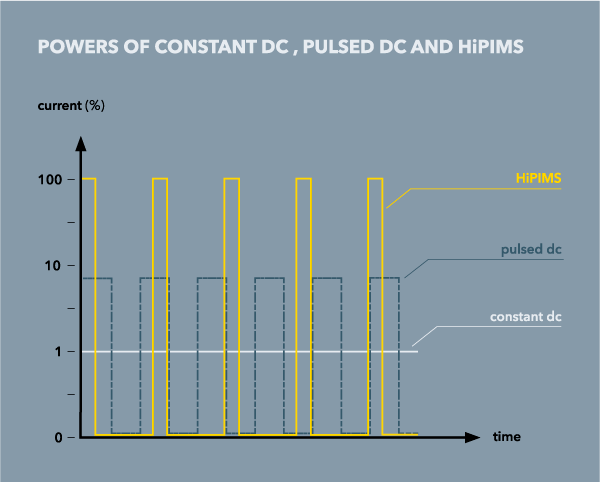

PVT found in HiPIMS (High Power Impuls Magnetron Sputtering) a crucial solution to overcome the significant drawback of magnetron sputtering: the low intrinsic energy of the process.

During HiPIMS short power pulses in the range of fractions of microseconds hit the substrates at very low duty cycles (<10%) at several kW per cm2 creating significant impacts of highly ionized coating material for very dense and smooth coatings.

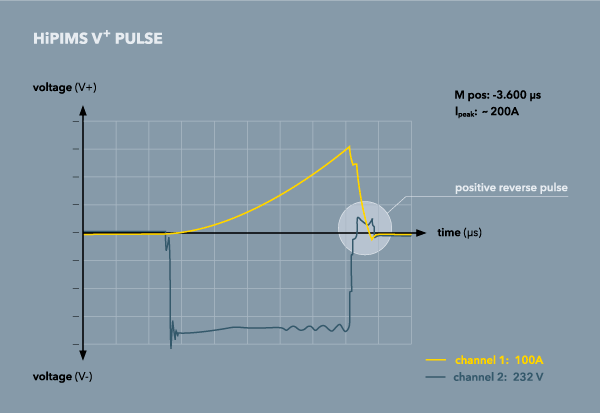

HiPIMS V+

HiPIMS V+ compensates for the low deposition rate by the positive reverse pulse after the high energetic negative pulse, thus increasing the deposition rate and tuning the coating properties.*

* developed by and applied in cooperation with Nano4Energy, Madrid, Spain