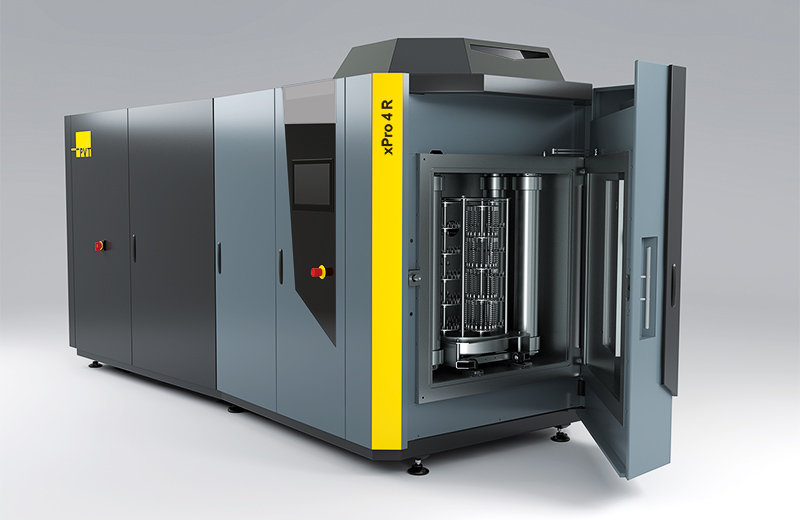

xPro4R

PVD Hard Coating System with HiPIMS V+-Technology and Rotatable Magnetron Sputtering Sources

The xPro4R is the most advanced industrial medium size hard coating system, based on the positive pulse HiPIMS V+ *-technology in combination with rotatable magnetron sputtering sources.

It is specifically designed for the deposition of high performance super-smooth, high density, hard coatings, such as AlTi-, AlCr-based, Si-, B-doped metal-nitrides and -carbo-nitrides. Such coatings are sputtered in HiPIMS V+ and DC-pulsed magnetron sputtering mode onto a variety of cutting tools, dies and moulds, components and consumer products for high wear resistance and advantageous tribological purposes. Such coatings can be deposited as nanostructured single or multi-layers.

Furthermore Rotatables can be used at significantly higher energy levels compared to planar magnetrons, thus positively influencing the economics of the process and properties of the coatings.

The xPro4R is characterized by:

- Robust system designed for the rigorous production environment using sophisticated vacuum coating technologies.

- Rugged construction marked by an extremely advanced highly refined design.

- Extreme reliability based on intelligent straightforward design and construction.

- The broadest spectrum of coatings and coating technology available in a single system at the lowest possible cost.

- Fully automatic, computer controlled, closed loop process control providing process repeatability, reliability and a user-friendly environment.

- The coating industry‘s broadest capabilities in the smallest footprint

Technical Highlights of the xPro4R:

HiPIMS V+ technology**

-

- HiPIMS V+ in combination with DC-pulsed magnetron sputtering

- Increased deposition rates and film ion incorporation

- compared to standard HiPIMS

- Tailoring of ion energy distribution

- Strong unbalanced magnetron configuration, allowing

- high film ion assistance

- Rotatable magnetron sputtering sources with high target utilisation and significantly reduced arcing

- No race track compared to planar magnetrons

- Feedback controlled reactive process

Short process time

-

- Efficient heating capabilities

- Efficient cleaning and etching cycle

- Short cycle times < 4,5

Improved part handling and fixturing

-

- Safest most manoeuvrable transport carts

- Easy to load and use carts with high load capabilities

Improved software design

-

- Extreme ease of use

- Highly reproducible runs

- High level of flexibility for custom tailored coating solutions

- Remote control and diagnostics

Improved thermal management

-

- Intensive water cooling

- Double walled construction

Most reliable components

-

- Brand name components

- Clever integration

System data

| Size of vacuum chamber | 940 x 1.150 x 1.165 mm (L x W x H) |

| Coating volume | 570 × 800 mm (Ø × H) |

|

No. of rotary platform |

1 pc |

| Pumping | 2 pcs double stage rotary vane pumps 1 pc Roots pump 2 pcs turbo-molecular pumps |

| Sources |

4 pcs rotatable magnetron sputtering sources |

| Power supplies | 2 pcs dc-pulsed power supplies @ 20 kW 2 pcs HiPIMS power supplies @ 20 kW 1 pc 20 kW HiPIMS bias power supply |

| Heater | 2 pcs, rated @ 12 kW each |

| Overall size | 4.865 x 1.855 x 2.435 mm (L x W x H) |

| Power | 150 kW, 400 V, 3 ph + N, 50/60 Hz |

System capacity

| Plasma volume | 570 × 800 mm (Ø × H) |

| End mills Ø 4 × 50 mm | 2.520 St. |

| End mills Ø 12 × 75 mm | 860 St. |

| Inserts ½″ x ½″ x 4 mm | 5.280 St. |

| Hobs Ø 80 × 80 mm | 160 St. |

| Hobs Ø 100 × 100 mm | 84 St. |

* HiPIMS = High Power Impulse Magnetron Sputtering

** V+ = HiPIMS with Positive Reverse Pulsing