In the past and for the future several different types of coatings got established or are under development and evaluation:

• Au (Gold)

• Metal-nitrides (Titanium-nitride and others)

• DLC (diamond-like-carbon in various compositions)

Such coatings can be deposited by PVD (physical vapor deposition) – processes such as:

- Magnetron-Sputtering

- Arc-Evaporation

- PECVD (Plasma Enhanced Chemical Vapor Depositen)

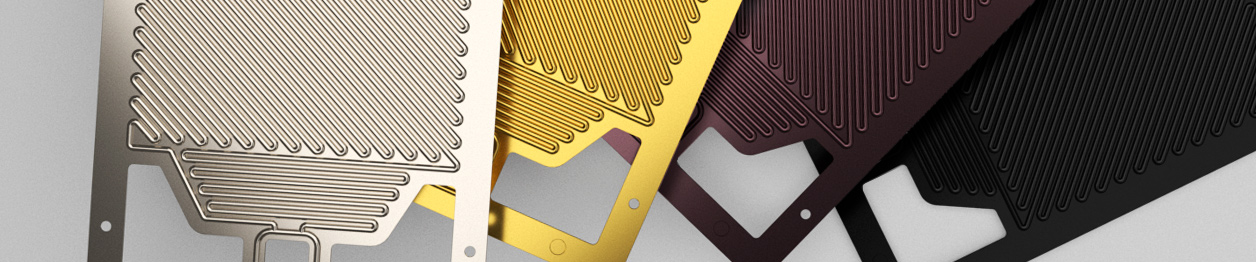

Coating Samples

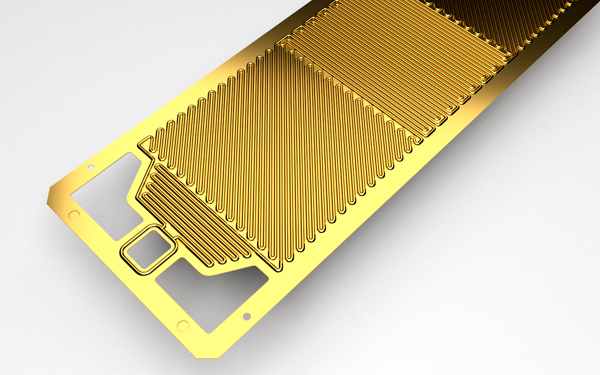

Metal-nitrides coated bipolar plates from an international bipolar plate manufacturer.

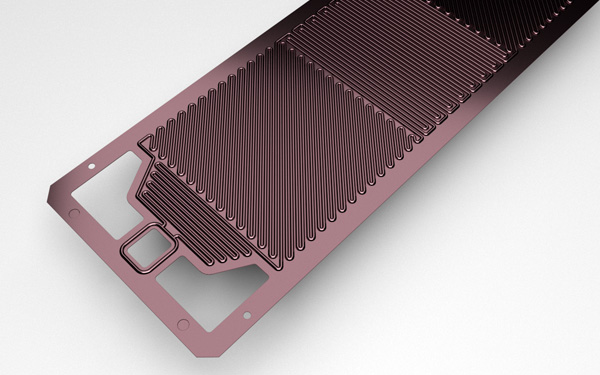

DLC coated bipolar plate from an international bipolar plate manufacturer.